DIY Gentle Soap Bar using Natural Oils and Butters:

A Beginner-Friendly Cold Process Soap Recipe

This DIY gentle soap bar recipe uses natural oils like olive oil, coconut oil, castor oil, and shea butter to create a mild, moisturizing handmade soap suitable for daily use. This guide explains soap-making safety precautions, ingredient benefits, exact measurements, and a step-by-step cold process method, making it ideal for beginners and hobby soap makers.

What Is Cold Process Soap Making?

Cold process soap making is a method where oils and butters react with lye (sodium hydroxide) through a chemical reaction called saponification, producing soap and glycerin. This method allows complete control over ingredients, superfat levels, and additives.

Soap Making Safety Precautions (Very Important)

Working with lye requires care and attention. Always follow these safety rules:

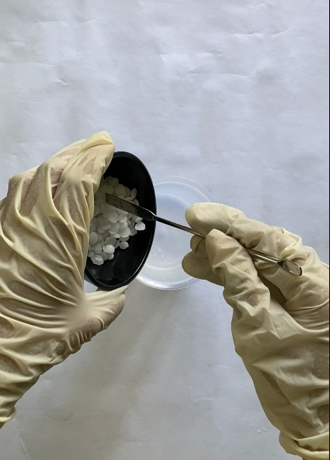

- Wear protective gear: gloves, eye goggles, mask, head cap, full-sleeve clothing, and closed shoes

- Never touch lye with bare hands

- Always work in a well-ventilated area

- Keep children and pets away

- Always add lye to water, never water to lye

- Add lye solution to oils, not oils to lye

- Clean soap equipment with gloves, preferably after a few weeks

- Use a soap calculator for accurate lye and water calculations

- Never replace oils without checking SAP values

- Allow adequate curing time for safe and gentle soap

Why Is Lye Necessary for Natural Soap?

Lye is essential for soap making. Without lye, oils will not turn into soap. During saponification, lye reacts with oils and water to form soap and glycerin.

- Sodium hydroxide (NaOH) → Solid soap

- Potassium hydroxide (KOH) → Liquid soap

Properly cured soap contains no free lye and is safe for skin.

Best Oils for a Gentle Soap Bar

This recipe is designed to be mild and conditioning:

Ingredient Function Breakdown

- Olive Oil (60%) – Highly moisturizing, gentle, and ideal for sensitive skin

- Coconut Oil (30%) – Provides cleansing and hardness

- Castor Oil (5%) – Creates stable, creamy lather

- Shea Butter (5%) – Adds extra conditioning and skin softness

- Sodium Lactate – Helps soap harden faster and unmould cleanly

- Kaolin Clay – Gentle exfoliation

- Charcoal Powder – Mild cleansing and oil-absorbing properties

- Lily Fragrance Oil – Adds a soft floral aroma

What Is Superfatting in Soap Making?

Superfat (SF) is the percentage of oils left unreacted after saponification, making the soap gentler.

Since this recipe contains 30% coconut oil, a 7% superfat level balances cleansing power and skin conditioning.

Ingredients Required (Exact Measurements)

Superfat: 7%

Oils & Butters

- Coconut Oil – 30% (45 g)

- Castor Oil – 5% (7.5 g)

- Olive Oil – 60% (90 g)

- Shea Butter – 5% (7.5 g)

Lye Solution

- Distilled Water – 41.57 g

- Sodium Hydroxide (NaOH) – 20.79 g

- Sodium Lactate – ½ tsp

Additives

- Kaolin Clay – ½ tsp

- Charcoal Powder – ½ tsp

- Lily Fragrance Oil – 4.5 g

Equipment Required

- 100 ml glass and heat-safe plastic beakers

- Steel stirring rods or spatulas

- Heating mantle or double boiler

- Soap mould

- Precision weighing scale (0.01 g accuracy)

- Measuring cups

- Gloves, goggles, head cap

Quick Process Overview

Melt oils → Prepare lye solution → Match temperatures → Blend → Add fragrance & clays → Pour into mould → Cure for 4–6 weeks

Step-by-Step Procedure

1) Measure all oils and butters into a heat-safe beaker and melt using a double boiler or heating mantle.

2) In a separate container, mix kaolin clay and charcoal powder with a small amount of measured oil.

3) Wear gloves, goggles, and safety gear before handling lye.

4) Measure distilled water and sodium hydroxide in separate containers.

5) Slowly add lye to water while stirring. Fumes and heat are normal. Once clear, add sodium lactate.

6) Allow both oils and lye solution to cool to 120–130°F (49–54°C).

7) Slowly pour lye solution into melted oils.

8) Blend using a stick blender in short bursts until light trace.

9) Add fragrance oil and mix gently.

10) Divide batter into two equal portions.

11) Add charcoal mixture to one portion and kaolin clay mixture to the other.

12) Pour into moulds—layered or textured as desired.

Unmould after 2–3 days and allow soap to cure for 4–6 weeks minimum.

How Long Should Handmade Soap Cure?

This soap contains 60% olive oil, which requires a longer curing time.

- Minimum cure: 4–6 weeks

- Longer curing = harder, gentler, longer-lasting bar

Common Mistakes to Avoid

- Swapping oils without checking SAP values

- Over-blending causing thick trace

- Unmoulding too early

- Skipping curing time

- Incorrect lye-to-water ratio

#cosmeticchemicals #chemicalsuppliersIndia #aseschem #naturalsoap #DIYgentlesoap #oliveoilsoap #saponification #DIYsoaping #howtomakeasoap

Disclaimer

This blog is for educational and informational purposes only. Always follow safety guidelines and use a soap calculator before making soap.

Popular Searches

Natural & Food Powders | Botanical Powders | Fruit & Vegetable Powders (Edible) | Herb Powders

FAQs

1. Is this soap suitable for sensitive skin?

Yes, the high olive oil content and 7% superfat make it gentle.

2. Can beginners try this recipe?

Yes, with proper safety precautions and accurate measurements.

3. Can essential oils replace fragrance oil?

Yes, but usage rates and skin safety must be checked.

4. Why does olive oil soap take longer to cure?

Olive oil produces a softer soap that hardens slowly over time.

Comments

good information regarding soap formation.